The industry is increasingly focused on speeding up antibody validation and biopharmaceutical research and development. Efficient execution of these processes, along with effective management of regulatory milestones, has become a central concern across the field. Creative Biolabs has recently officially launched a full-process service portfolio covering "from discovery to production", providing biopharmaceutical companies with faster, more stable, and more scalable technical channels.

"We have observed that there is an increasing number of projects with a gap between the early-stage validation and the later-stage production," said scientists from Creative Biolabs. "To streamline the process, an integrated technology chain has been developed, which enables workflows ranging from sequence validation to the generation of cGMP-compliant antibodies."

High-throughput antibody production

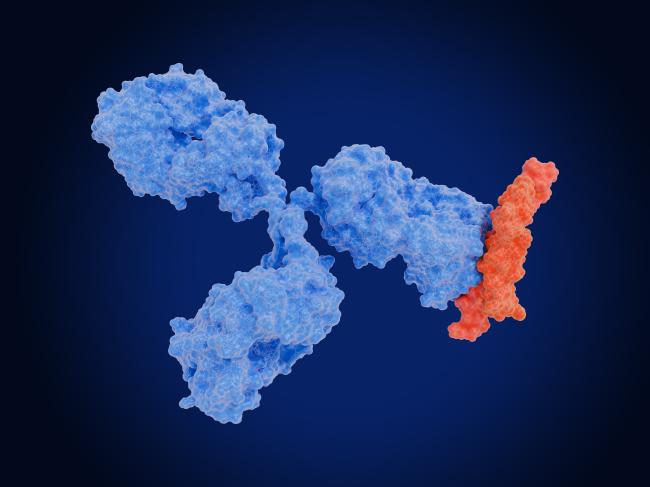

Creative Biolabs' high-throughput antibody production platform is specifically designed for rapid expression and screening, capable of handling tens to thousands of antibody sequences simultaneously within a short period. Batch-to-batch consistency is enhanced greatly by the automated upstream expression and purification system, which is compatible with various formats, including IgG, Fab, scFv, and bispecific antibodies.

This platform is designed to help teams rapidly convert sequences into purified antibody materials, enabling candidate molecules generated through single B-cell screening, phage display, or AI design to be rapidly put into functional verification, thereby shortening the early R&D cycle.

One-stop CDMO: From Process Development to cGMP Production

For projects entering the clinical stage or preparing for large-scale production, Creative Biolabs offers a one-stop CDMO service covering cell line construction, process development, scale-up production, quality control testing, and fill-finish and batch release. This platform supports multiple types of biologics, including monoclonal antibodies, bispecific antibodies, Fc fusion proteins, enzyme proteins, and viral vectors, with scales ranging from R&D level to clinical and commercial levels.

"We work as an integrated engine, ensuring every transition—from upstream process to downstream purification—remains scientifically robust and regulatory-ready," the scientist added.

Biosimilar development, facilitating global expansion

With the patent expiration wave approaching, biosimilars are becoming a key focus of strategic planning for major pharmaceutical companies. Creative Biolabs' biosimilar development services cover similarity assessment, cell line and process establishment, analytical characterization, quality control, and IND support, helping enterprises advance their biosimilar pipelines with more controllable costs and more predictable timelines.

This service system is not only applicable to monoclonal antibody products but also suitable for multiple types of products, such as Fc fusion proteins and recombinant proteins, providing a technical foundation for enterprises to enter the international market.

Website: https://www.creativebiolabs.net/